New Generation of Hydraulic Jet Pumps Recent developments have made a new generation of hydraulic jet pumps a viable solution for a wider range of wells while requiring much less maintenance for the end user.

The benefits of the jet pump are:

• No moving parts down-hole

• Ability to produce sands and solids

• No gas locking

• The power fluid can be treated with corrosion and scale inhibitors

• Ease of optimization with software

• Production rates can be changed by adjusting injection pressure and rate

• Capability of producing high volumes of fluid and ease of serviceability because nozzle and throat can be hydraulically retrieved with no rig or wire line.

|  |

The fluid enters a diffuser section that converts the jet kinetic energy to pressure. This pressure is harnessed to drive the fluid to the surface.

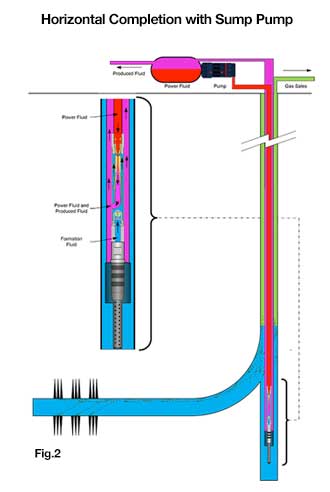

The process of lifting the water utilizes the combination of a jet pump with internal tubing inside slightly larger tubing, which is run in gas wells. The gas can then flow up the annulus between the water lift string and the non-liquid-loaded completion.

The oil jet pump uses the momentum and force of one fluid to move another fluid. It consists of :

The nozzle – This creates velocity by converting the pressure of the power fluid.

The intake – This directs the produced fluids into the jet portion of the pump

The mixing tube – This is known as the “throat”. It is where the produced fluid and the power fluid converge, reaching its average velocity.

The diffuser – This is where the mixed stream’s velocity is converted back into pressure, and is forced up the annulus.

With the oil jet pump, the small, sleek design facilitates the retrieval of the pump from deviated, or even horizontal wells. It is accomplished by manipulating the surface valves and the reversal of the circulation of the fluid with the plunger pump. Wire lines, pulling units and work over rigs are all alleviated, reducing operation costs to the well operator.

The oil jet pump operates at practically unlimited depths and well deviations, and has an extremely high tolerance to entrained gases and solids. There are also no moving parts within the oil jet pump.

JJ Tech is a leader in creation of artificial lift within the G&O industry, utilizing patented oil jet pump technology.