Q&A Interview: Replaced Failed Jet Pump Assembly

Interview conducted by a 3rd party with an Operator who recently replaced a competitor’s equipment with JJ Tech equipment.

Jet Pump Artificial Lift Succeeds in Flood Zone

The JJ Tech Jet Pump System enables well operators to continue production despite flood waters with equipment that requires little to no maintenance.

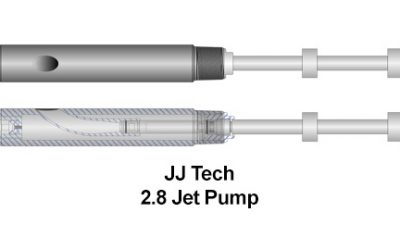

2.8 Jet Pump Operates 10+ Years Without Workover

McMullen County well with JJ Tech 2.8 Jet Pump has produced continuously for over ten years without any workover. Using the high quality JJ Tech Jet Pump along with a good treatment program has saved the operator from any workover costs.

ULTRA-FLOW™ Jet Pump System Slashes Workover Costs, Yields Higher Fluid Production

With the combination of the reliability of the JJ Tech ULTRA-FLOW™ skid packages and the lack of workovers to the well since installing the JJ Tech 2.3 Jet Pump this has been a successful venture for the customer.

How an Operator Decreased Operating Costs by Replacing an ESP with a Hydraulic Jet Pump

Customer decreased well operating costs by replacing 4 ESP’s (Electric Submersible Pump) with JJ Tech Hydraulic Jet Pumps in a 12 month period.

How an Operator Decreased Operating Costs by Replacing an ESP with a Jet Pump

Customer replaced 6 ESP’s (Electric Submersible Pump) in a 4 year period.

Accelerated Frac Flowback

JJ Tech’s FRAC-EVAC recovered 15,200 bbls of frac fluid (100% recovery) and 2,100 bbls of oil in addition to frac fluid, in just 27 days. The same recovery volume would have taken a conventional rod pump system 5 months at a maximum rate of 100 BBLS per day.

How the ULTRA-FLOW™ Jet Pump System Slashed Deviated Well Costs

Reliable, cost saving ULTRA-FLOW™ System installed in shallow deviated wellbore increases production and slashes workover costs. Increased production from 250 to 300 bbls / day (20% increase). No moving parts down hole eliminates the possibility of tubing damage from rod wear (and there are no rods to part).

Efficient Frac Sand Removal in Mississippian Lime Well

Operator cannot produce well for more than 4-5 days due to leftover frac sand in wellbore. Installed JJ Tech Reverse Flow HSP Jet Pump to bring frac sand to surface along with production. Well has proven productive, and JJ Tech Jet Pump recovers 1-5 gallons of 20/40 mesh frac sand to surface daily.

How an Operator Used Artificial Lift in a Highly Corrosive Environment

Artificial lift in a highly corrosive environment where producing fluid up the casing is not an option with any type of lift. Well makes 4% CO2 and 5,000 ppm (0.5%) H2S.

How an Operator Increased from 180 bpd to 300 bpd in a Crooked Hole

Artificial lift in “crooked” deviated wellbore. Rod pump continuously fails due to tubing and rod wear. Well has to be worked over every 3 – 4 weeks.

JJ Tech D-35 ULTRA-FLOW System Optimized for CBM Well Proves Successful for Australian Operator

Artificial lift in “crooked” deviated wellbore. Rod pump continuously fails due to tubing and rod wear. Well has to be worked over every 3 – 4 weeks.