Artificial lift is used to produce 90% of oil and gas wells worldwide.

Jet Pump Artificial Lift Well Types

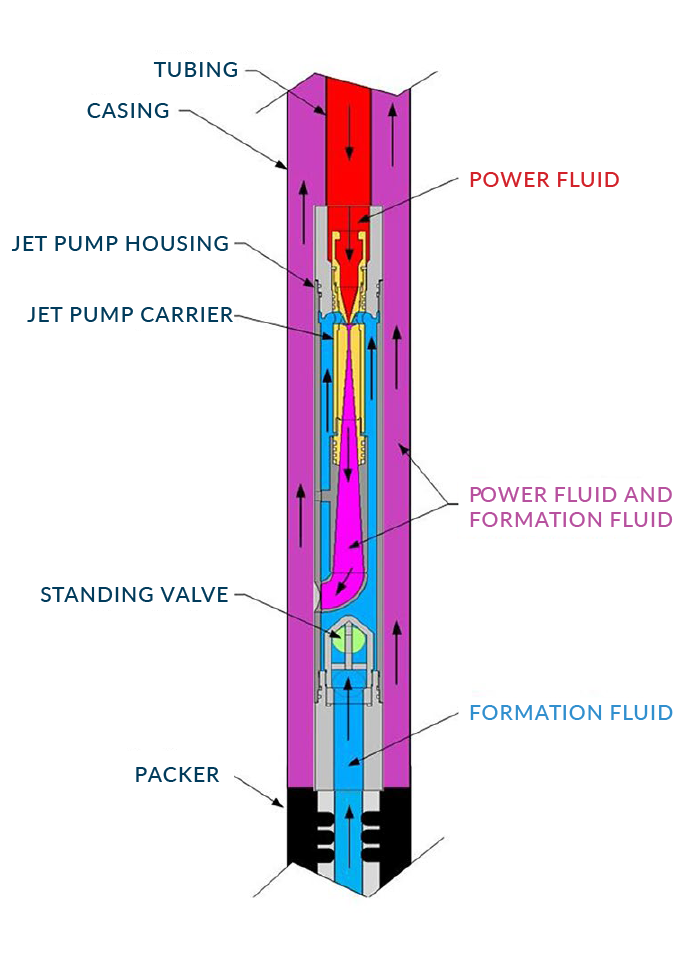

Hydraulic jet pumping offers many benefits to operators. Most hydraulic jet pump users experience a reduced number of workovers, which lowers overall lease operating expenses. Unlike other forms of lift, which have specific well-type applications, Hydraulic Jet Pumps can be used in virtually any well type. Whether you have a vertical well, horizontal well, or need to remove water from a natural gas well, JJ Tech’s ULTRA-FLOW Jet Pump System could be your most effective solution.

Vertical Wells

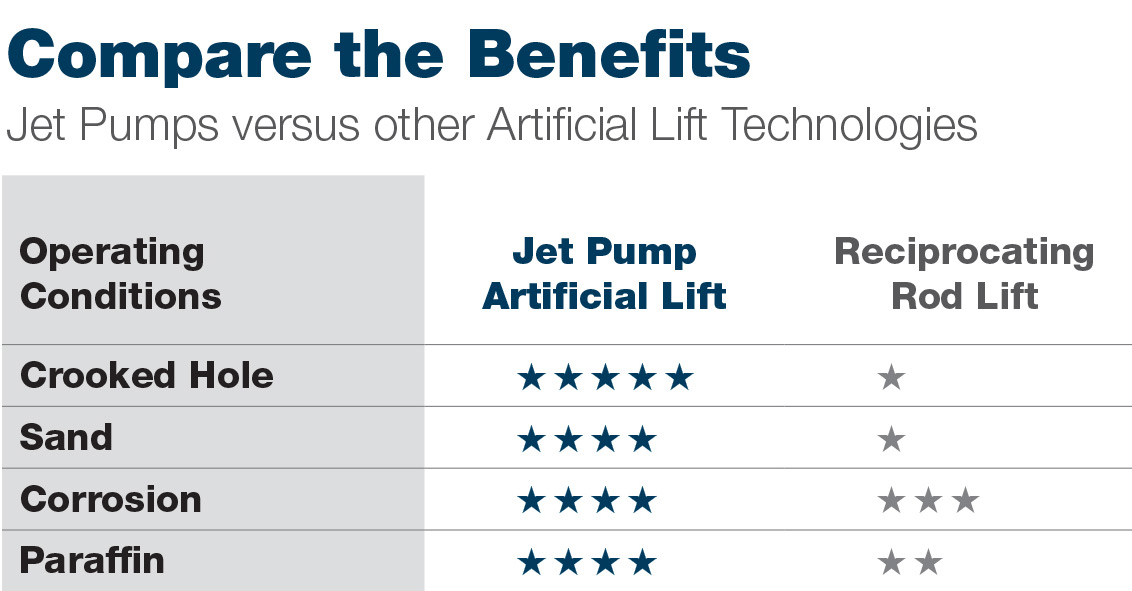

Depending on depth, artificially lifting a vertical well with a Rod Lift is the most common and typically the most efficient form of lift – provided the well was drilled straight, and it does not produce sand or paraffin. Regardless of what challenges a vertical well might present, workovers are expensive and negatively impact your bottom line. With a Jet Pump system there is no mechanical connection from the surface to the downhole pump, so well deviations do not cause issues. Rod Lifts and PC pumps both have a string of metal rods (reciprocating or rotating) inside metal tubing, which can cause the rods to part and/or cut holes in the tubing, almost always requiring a workover to correct.

Since there are no moving parts inside a Jet Pump, sand and solids production do not cause rapid wear on sealing surfaces or impellers. In other types of lifts, sand or solids reduce efficiency or can cause complete downhole pump failure, requiring an expensive and time consuming workover. Conversely with a Jet Pump system, if components show signs of wear over time, the Jet Pump can be reverse-circulated to surface, serviced, and pumped back into place without the need for a workover rig, with downtime of hours instead of days.

Horizontal Wells

Producing hydraulically frac’ed horizontal wells by conventional artificial lift methods becomes more difficult as bottomhole pressure decreases. However, with a Jet Pump being free of mechanical connection from the surface to the downhole pump, it is possible to lift from much deeper (TVD) in the well to increase drawdown. Jet Pumps can operate in the horizontal section (lateral) of the wellbore. Rod lifts and ESPs typically need to stay in the vertical section of the wellbore, limiting drawdown typically to the kick-off point (beginning of the curve) in the well.

Natural Gas Wells – Vertical and Horizontal

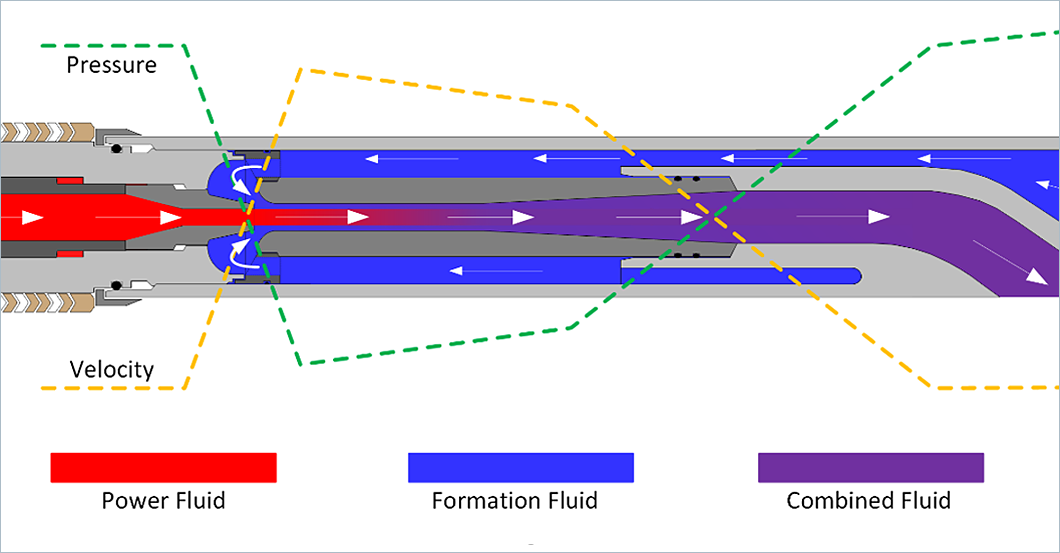

The ULTRA-FLOW Jet Pump System can also be used to produce liquid-loaded natural gas wells. The Jet Pump does not actually produce the natural gas from the well, it produces the liquids that hold the gas back. Without artificial lift, liquids can load up in a gas well over time, creating a “hydrostatic head” that limits gas production.

The Jet Pump is used to produce liquids from the well, reducing this hydrostatic head, allowing the gas to flow with less restriction thus increased production. Concentric strings of tubing are used to produce the liquids from the well, and the natural gas flows more freely up the casing annulus to the surface.

Vertical gas wells are typically produced with a Jet Pump from below the perforations. Horizontal gas wells are typically produced from the “heel” section of the well (65 – 80 deg).

Featured Articles

Compare Artificial Lift Technologies

How Does a Jet Pump Work?

JJ Tech Jet Pump Selector

TALK TO AN EXPERT

Our team of experts specialize in resolving your challenging oil and gas well production problems. Talk to JJ Tech about analyzing your well at no cost and let us show you how we can help optimize your well production and lower your operating costs.