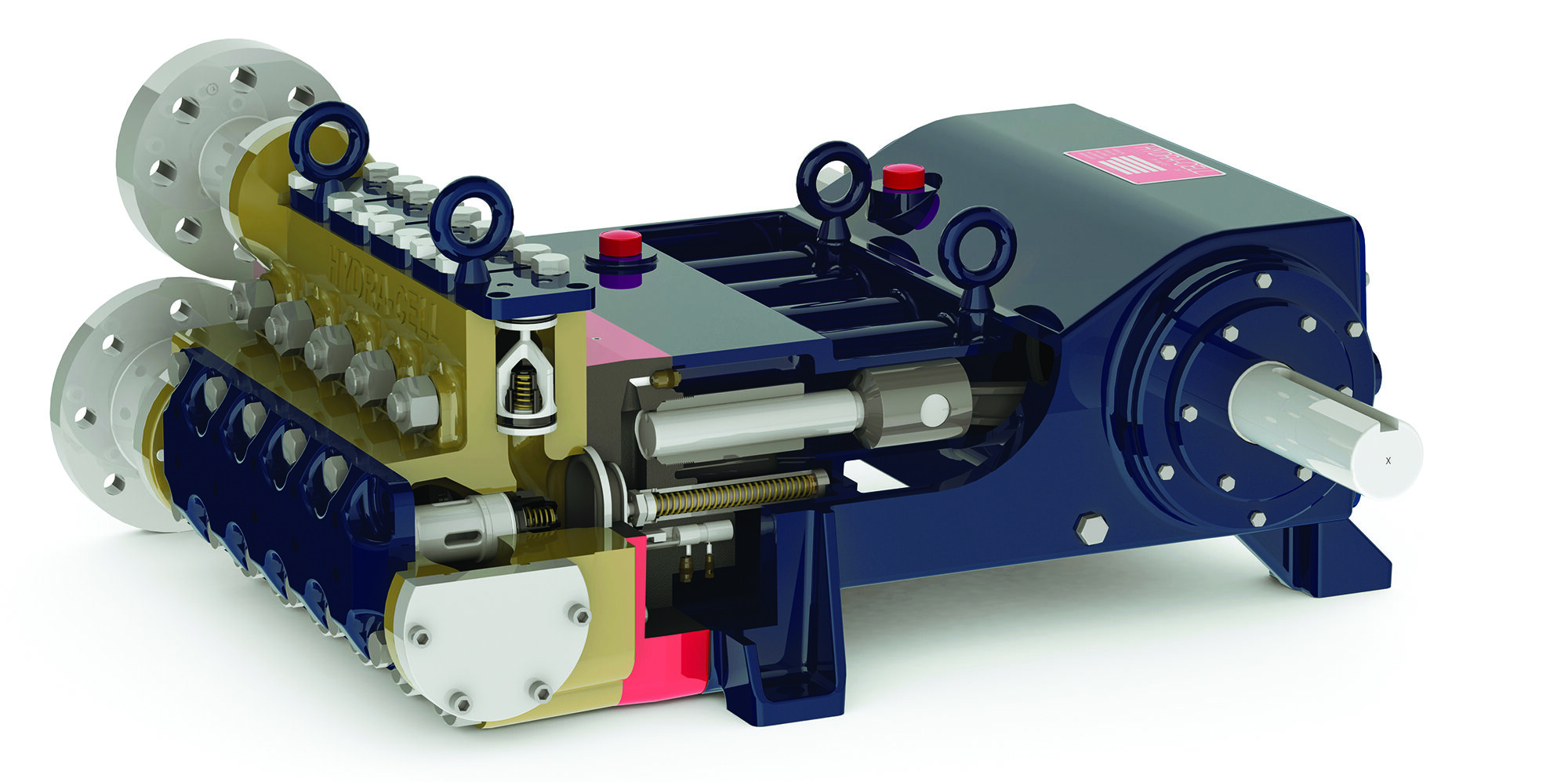

Wanner™ Hydra-Cell® Pro Seal-less Diaphragm Pumps to API 674 and API 675 Standards

Wanner™ Hydra-Cell® Pro T & Q Series “Packing-Free” Pumps offer high pressure performance with exclusive low-pulse, linear flow that reduces pump energy costs and stress. Wanner’s patented, seal-less diaphragm design eliminates packing and plunger wear, leakage, emission, external lubrication, and time-consuming field adjustment. This results in lower costs for maintenance and delivers a longer service life than traditional packed pumps. Manifold options include Nickel Aluminum Bronze (NAB), 316L Stainless Steel (SST), Duplex Alloy 2205 Stainless Steel, and Hastelloy CX2M depending on model.

Hydra-Cell D-Series Diaphragm Pumps (Up to 40 HP)

Hydra-Cell T60 Series Diaphram Pumps (60HP)

Hydra-Cell T100 Series Diaphragm Pumps (100 HP)

Hydra-Cell Q155 Series Diaphragm Pumps (155 HP)

Hydra-Cell T200 Series Diaphragm Pumps (200 HP)

Hydra-Cell Q330 Series Diaphragm Pumps (330 HP)

- Seal-less design separates the power end from the process fluid end, eliminating leaks, hazards, and the expense associated with seals and packing.

- Can operate with a closed or blocked suction line and run dry indefinitely without damage, eliminating downtime and repair costs.

- Unique diaphragm design handles more abrasives with less wear than gear, screw-type or plunger pumps.

- Hydraulically balanced diaphragms to handle high pressures with low stress. • Provides low-pulse, linear flow due to its multiple diaphragm design.

- Lower energy costs than centrifugal pumps (H-type) and other pump technologies. • Rugged construction for long life with minimal maintenance.

- Compact design provides a variety of installation options – T100 and Q155 models

- Flow rate controllable to API 675 performance standards to provide ultimate optimization of Jet Pump production

Wanner Hydra-Cell Pro Pumps

T & Q Series Pumps exceed API 675 standards for accuracy and repeatability.

Get Longer Run Times with Seal-Less Design.

Wanner Hydra-Cell Pro pumps feature a seal-less design with no packing or seals to wear, leak or fail. The pump’s plungers/cylinders are submerged in oil, so no external lubrication is required. These benefits of the Hydra-Cell Pro result in lower costs of ownership and longer run life than conventional packed plunger pumps.

Reduce Maintenance Costs.

Hydra-Cell Pro pumps can operate up to 6,000 hours between lubricating oil changes. Their robust design tolerates non-ideal operating conditions, and hydraulically-balanced diaphragms handle high pressures with low stress. They don’t rely on the fluid being pumped for lubrication and can operate with a closed / blocked suction line and run dry indefinitely without damage, eliminating downtime and repair costs.

Flexible Diaphragm Pumps in the Materials You Need.

Hydra-Cell Pro diaphragm pumps are available in many materials to fit your application and ensure maximum pump life in the most demanding environments The design enables you to easily interchange pump head materials to resist corrosion, chemical attack and abrasive wear. Hydraulically-balanced diaphragms can pump low to high-viscosity liquids throughout the entire pressure range of the pump.

Handle More Abrasives.

The seal-less design and check valves enable Hydra-Cell diaphragm pumps to work with particulates that would damage other pumps. They tolerate abrasives, solids and particles up to 800 microns and 9 Mohs without needing fine filtration. They can also pump acids and liquids with up to 40% dissolved solids. In addition, these diaphragm pumps don’t have tight tolerances vulnerable to corrosion or particles.

Reduce Risks. Protect the Environment.

T and Q Series pumps feature the Hydra-Cell Pro seal-less design, eliminating leaks, hazards, and the expense associated with seals and packing. The seal-less design isolates the power end from the process fluid end, so pumped liquids and volatile organic compounds (VOCs) are completely sealed from the atmosphere. Mechanical efficiencies of 80 to 90% provide significant energy savings compared to other pumping technologies.

High and Low Pressure Hydra-Cell Diaphragm Pumps

JJ Tech’s Patented Ultra-Flow production system is unique to the industry in that it combines a Hydra-Cell Diaphragm Pump to power the JJ Tech downhole Jet Pump. The Hydra-Cell pump has no packing to wear or leak, and the plungers never come into contact with the fluid being pumped. These features reduce the overall maintenance costs associated with operating the system.

Hydra-Cell Pump T&Q Series Diaphragm Pumps are manufactured in the US by Wanner Engineering and are available in 100, 155, 200, 330 Horsepower. Hydra-Cell Pumps have pressure capabilities up to 5000 psi. T&Q Series Low Pressure Pumps are also used for saltwater disposal and are capable of pumping from 2300 up to 11,200 BPD.

The (Wanner) surface pump has proven to be very reliable – no messy leaks, and very little downtime. Chris Lamberth and Jon Mullins have done a great job for us. We are very satisfied with the service as well as the system.

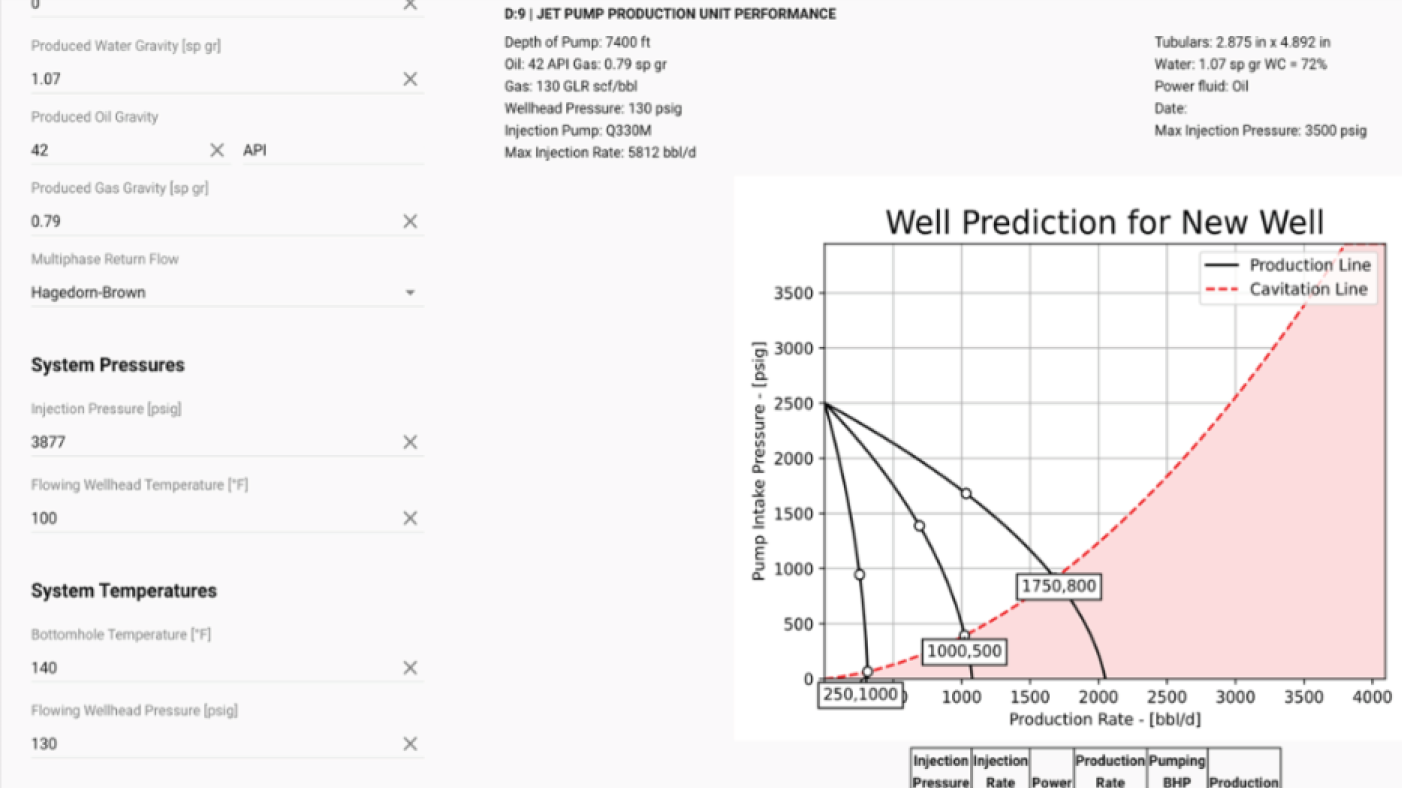

CALCULATE JET PUMP PERFORMANCE

Jet Pump Design & Optimization App

Our powerful app, available at no cost to qualified operators, lets you input your specific well conditions and plot predicted jet pump performance. Jet pump optimization features are quick and easy.

TALK TO AN EXPERT

Our team of experts specialize in resolving your challenging oil and gas well production problems. Talk to JJ Tech about analyzing your well at no cost and let us show you how we can help optimize your well production and lower your operating costs.