Background

The project is located in an area in Louisiana where floodwaters can reach as high as 62 feet. Very often well operators in the area are forced to shut-in wells because well or pump maintenance requires a boat to access the site.

Challenges

Oil wells like the Frank Davis SL 21339 No. 1 located in the batture, the land located between the Mississippi River and its levees, have always presented challenges to operators. Operators treat this area, which is dry land most of the year, like marsh or offshore areas. When the Natchez gauge is at 37.0 feet or above, the Frank Davis SL 21339 No. 1 becomes inaccessible by land. Tank batteries are typically raised on earthen mounds with pumps located on structures elevated above the normal high-water stage. When the batture floods, operators are forced to work from boats. Major problems during high water often result in wells being shut in, resulting in loss of income. (For pic 1, see Case Study.)

Since the advent of hydraulic jet pumps, many of these wells have been converted to this form of artificial lift, with the power fluid pumps usually located at the tank battery. However, maintenance and service issues still require the use of boats during high water. Unusually high water requires the wells to be shut in, and it sometimes results in the removal of the pumping equipment and associated prime movers. When economically justified, the tank battery and pumping equipment is located on the protected side of the levee. The power fluid and flow lines run across the levee to an elevated wellhead. This eliminates nearly all of the previous maintenance and service issues other than retrieving the downhole pump, which is an unusual occurrence.

There are several considerations when using this method, not the least of which being the cost, but also right of ways, government regulations, environmental concerns, time constraints necessary for installation, and longevity of the piping after installation.

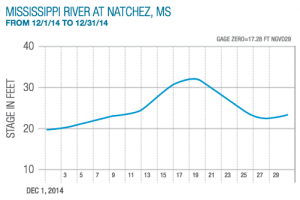

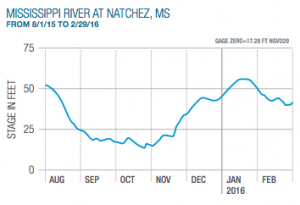

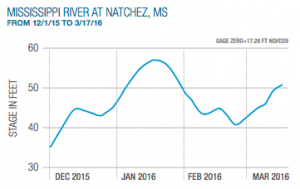

When the Frank Davis SL 21339 No. 1 was completed Dec. 26, 2014, the Mississippi was beginning another historical event. Never in recorded history had it performed in such a manner. The so called 500-year flood of 2011 saw the river reach the record stage of 61.95 feet above the previous record stage of 58.04 feet in 1937. But this rise was even more exceptional than 2011 because it came and stayed. The stage at Natchez was above 50.0 feet in August 2015. Even more unusual was when it did fall it only stayed low for 110 days before rising back to 56.7 feet and cresting on Jan. 17, 2016.

The Frank Davis SL 21339 No. 1 is a very good well. There are several pay zones in what geologically indicates to be a several well play, and when the well was completed, oil was selling for over $100 per barrel. Time was a huge factor in the completion. There were delays in getting right of ways and Corps of Engineers permits, plus environmental issues.

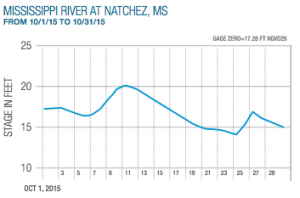

When the river level dropped low enough in October 2015 to allow work, there was concern that there would not be enough time to complete the job before the expected winter rise.

Strategy

Aldridge Operating and the owners decided to use the JJ Tech production system was ideal in a flood zone due to its low downtime, less routine maintenance and minimal environmental impact versus other forms of artificial lift. The remaining issues surrounding how quickly the flow lines could be run were considered as there were numerous ridges and sloughs to cross. (For pics 2 & 3, see Case Study.)

Other problems such as deciding which pipe product could meet the stringent environmental requirements, corrosion issues and overall costs were included in the discussion. As the owners/operator expected to locate at least one more well near the Frank Davis SL 21339 No. 1, the lines had to handle at least twice the maximum predicted volume of fluid. William Coleman, the inventor of JJ Tech’s downhole pump, had used coiled tubing as a solution for problems on many projects where conventional threaded pipe was not appropriate. After exploring several other systems, including fiberglass pipe and welded and coated line pipe, the decision was made to use coated coiled line pipe. Global Tubing had developed an externally coated coiled line pipe for offshore use, which had a successful history in that environment.

As soon as river conditions allowed the right of way, ditching and levee crossing to be completed, the installation of the coiled line pipe began. The coiled line pipe arrived at the location Oct. 19, 2015. (For pic 4 & 5, see Case Study.)

Execution

The project took five days from mobilization to de-mobilization. The actual pipe stringing took only three days with 5,700’ on average installed per day. (For pic 6, 7 & 8, see Case Study.)

The contractor on the job was Oilstone Energy Services. During the project they performed pull-through in six casing conduits at the levee crossing in less than four hours. (Pic 9 see Case Study)

The project was completed Oct. 23, 2015. As the wellhead was over 8,600’ from the tank battery, the flowline and power fluid lines were run together. The total pipeline length was 17,230’ of 2 ½” nominal ID (2 7/8” actual OD) Schedule 40 0.203” WT A53/X52C/X65C grade coiled line pipe. The pipe was delivered on six uninterrupted reel lengths of up to 3,100’ each. (For pic 10, see Case Study.)

Results

Using Global Tubing’s offshore, externally coated, coiled line pipe and the JJ Tech’s jet pump artificial lift system, the well was able to run uninterrupted during record flood waters.

By Dec. 4, 2015, the river stage was up to 38.0 feet, covering the wellhead location. On Dec. 6, 2015, the jet pump was dropped into the well from a boat, and production was established the following day. The vast majority of wells located in the batture have been shut in since this time period. Even though the river stage was measured at 50.53 feet on March 17, 2016, the Frank Davis SL 21339 No. 1 has continued to produce uninterrupted.