The JJ Tech Gas Well Dewatering Solution

How The Gas Well Dewatering Solution Works

The JJ Tech hydraulic jet pump utilizes the Venturi Effect to pull wellbore fluids into a flow stream that is pumped downhole and back up again through a concentric string configuration. The key components of the jet pump assembly are flow-reversible and don’t require a service rig intervention to retrieve, inspect, service or change them. Pump component changeouts are a one-person operation that requires only one to two hours to perform. The jet pump can run on the end of the integral joint or coiled tubing inside of standard production tubing.

The innovative, patented JJ Tech hydraulic jet pump design uses larger fluid input areas and cleaner flow geometries, allowing operation with efficiency equal to or greater than conventional artificial lift systems. These features also facilitate the movement of solids, i.e. sand, through the jet pump, making it ideal for production with high solid content.

JJ Tech’s jet pump is the downhole component of the company’s patented ULTRA-FLOW production system. It is combined with a T100 series high-pressure diaphragm surface pump, developed for JJ Tech by Wanner Engineering Inc. This rugged, reliable pump greatly reduces environmental and maintenance issues associated with conventional triplex pumps. The T100S, rated at 5000 PSI and 905 BPD is well suited for concentric string completions used with gas well dewatering, where smaller fluid conduits require higher pressures due to fluid friction through the smaller strings of pipe.

The Wanner surface pumps are closed systems with cartridge-type check valves and diaphragms for ease of maintenance and lower operating costs. Units are configured with natural gas engines or electric motors with variable-frequency drives (VFDs) to reduce operating costs and pump wear.

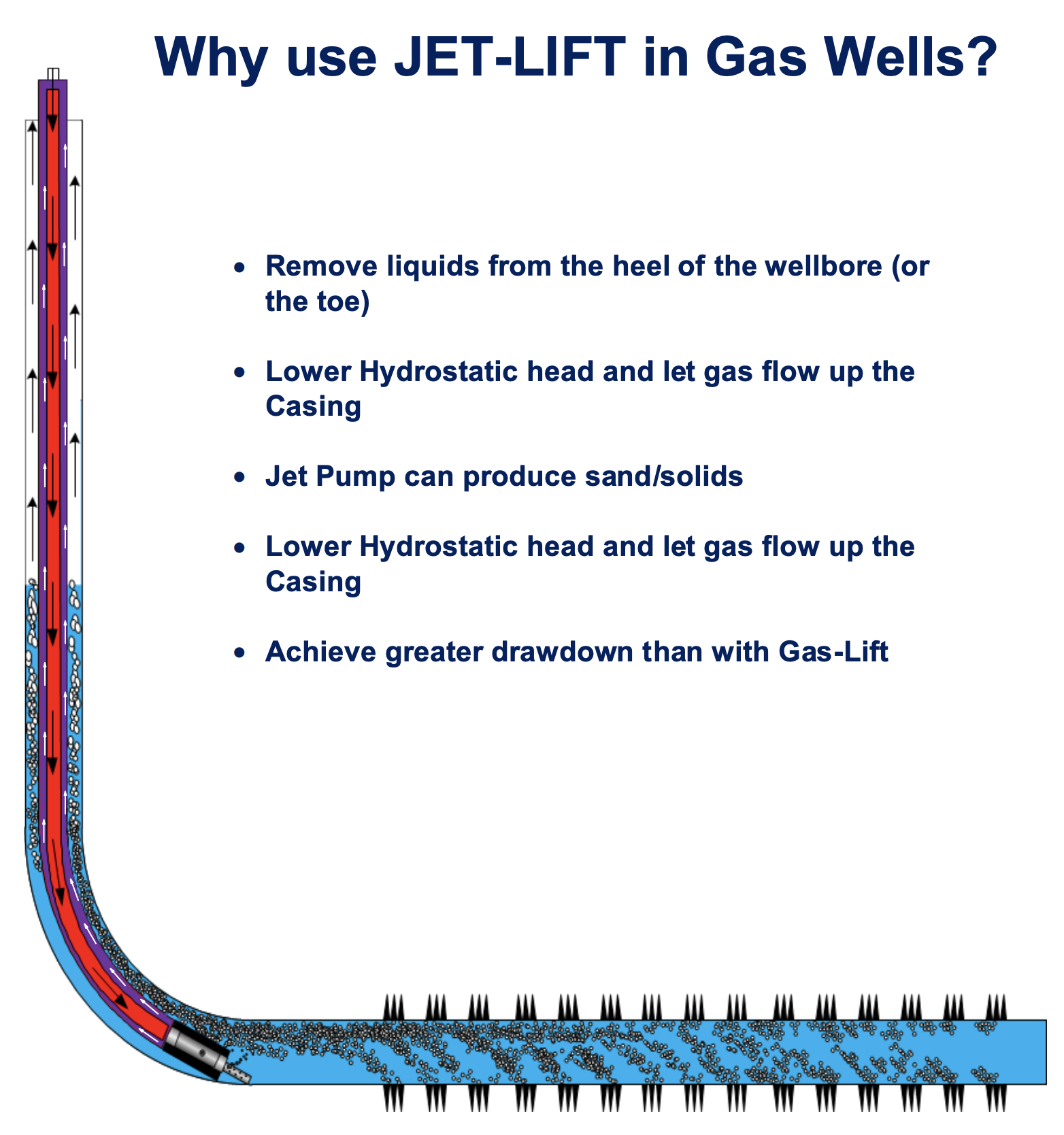

Advantages Of The JJ Tech Gas Well Dewatering Solution

- There are no moving parts downhole.

- It can move large volumes of fluid with moderate to high solid (sand) content.

- It increases production rates as hydrostatic head is reduced.

- It increases recoverable reserves as more gas can move into the wellbore.

- Proprietary software provides formation monitoring and performance optimization.

- They can run horizontally.

TALK TO AN EXPERT

Our team of experts specialize in resolving your challenging oil and gas well production problems. Talk to JJ Tech about analyzing your well at no cost and let us show you how we can help optimize your well production and lower your operating costs.