For Wells with High Concentrations of Corrosive Gases

Some produced wells have high concentrations of corrosive gases such as H2S and CO2. These corrosives can damage metal tubulars downhole. Since the well casing is cemented into the ground and can’t be removed, it’s critical to keep these corrosives from damaging the wellbore.

JJ Tech’s SELECT-JET Pumps allow you to operate in “reverse flow” and inject clean/treated power fluid down the casing and return the corrosive fluids up the tubing (which is replaceable). Jet pumping with SELECT-JET allows you to run in normal or reverse flow without changing the bottom hole assembly.

Reduce Costs and Increase Oil and Gas Well Production

JJ Tech employs a combination of patented technologies to provide a tailored artificial lift solution designed to improve production and significantly lower overall operating costs over the life of your well.

SELECT-JET Pumps

Our unique design and manufacturing process results in best-in-class, efficient lift performance. Operators have the flexibility to place it in wells where other forms of artificial lift can’t operate.

Hydra-Cell Pro Diaphragm Pumps

The seal-less, packing-free design ensures a reliable, efficient way to power the JJ Tech jet pump.

Hydraulic Jet Pump Design & Optimization App

Using the actual surface and subsurface data from your oil or gas well, our Hydraulic Jet Pump Design & Optimization App lets you plot current jet pump performance and optimize for the future. Our app ensures the downhole jet pump is operating as efficiently as possible, thus maximizing overall production levels.

The Challenge

Producing wells with concentrations of corrosive gases such as hydrogen sulfide (H₂S) or carbon dioxide (CO₂), can cause damage to metal tubulars, casings and pumps including sulfide stress cracking and hydrogen-induced cracking, which compromise the structural integrity of equipment. These risks also extend to safety, environmental impacts, operational complexity and production challenges, with the likelihood of increased maintenance and repair costs.

JJ Tech Jet Pump Solution

JJ Tech Hydraulic Jet Pump systems work very well in corrosive environments and offer a number of advantages. As a “closed loop” system risk to the environment is minimized, and Hydra-Cell Pro surface pumps have zero VOC emissions when operating under normal conditions. Hydraulic Jet Pump systems circulate fluid through both the tubing and casing, so chemicals can be injected into this “Power Fluid” to circulate and continuously treat to prevent tubular corrosion. SELECT-JET and Hydra-Cell pumps are offered in many corrosive-resistant materials, including Hastelloy and Inconel, plus 316 Stainless Steel and Duplex alloys.

Jet Pump Advantages

Greater Reliability

With no moving parts, JJ Tech jet jumps produce wells with sand or solids with far less damage potential to the downhole pump. If, over time, jet pump parts do become worn, a workover rig is not needed for replacement.

Reduced Workover Costs

With a JJ Tech jet pump, three- to five-year run times between workovers is not uncommon. Our jet pump systems also allow for chemical treatment for tubing and casing on a continual basis.

Increased Production

A JJ Tech jet pump can also provide increased production when other forms of lift are unable to provide the desired drawdown on a producing formation.

Related Case Studies

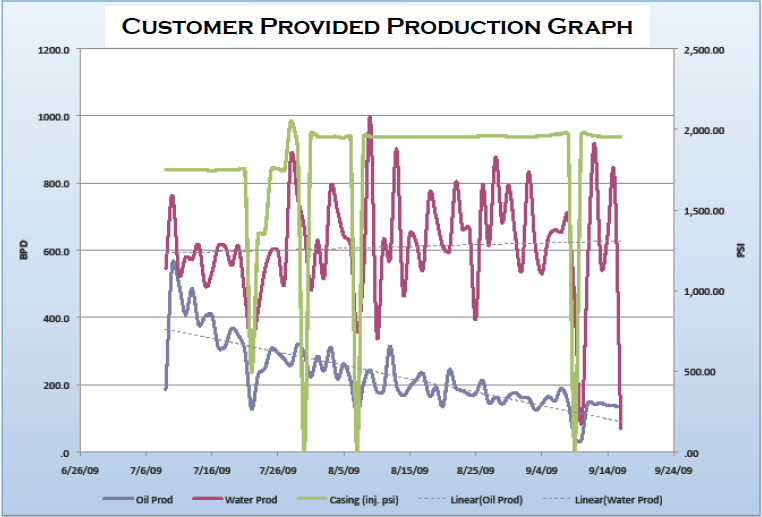

Artificial Lift in a Highly Corrosive Environment

TALK TO AN EXPERT

Our team of experts specialize in resolving your challenging oil and gas well production problems. Talk to JJ Tech about analyzing your well at no cost and let us show you how we can help optimize your well production and lower your operating costs.